The method, developed by researchers from the Engineering Fluid Dynamics Group at the UT, was published in the prestigious journal Advanced Materials. With their novel approach, the scientists ejected a liquid fluid jet in the air, that hardened when illuminated by UV light. By varying the UV exposure and the shape of the fluid stream, they were able to create microparticles in different shapes and sizes.

Microparticles

Microparticles are tiny bits of several micrometers to one millimeter in size. Typically, they measure about the thickness of a hair. They exist in nature, for example as pollen, but also sand, powdered sugar and flour are considered microparticles. Industrially-made microparticles offer a stunning number of applications in medicine, biology and chemistry. For example, hollow microparticles may be mixed with a substance to lower its density, while expanding microparticles are used as a fire-retardant coating on steel constructions.

Applications in medicine are particularly promising. Microparticles can be injected in the blood stream, to better visualize blood flows using ultra sound. But they can also be used for improved medication delivery as time-release micro-capsules, or to build patches with microneedles for painless injections. Radioactive microparticles, that are precisely delivered at a tumor site, can be used to kill tumor cells, with limited damage to surrounding healthy tissue.

High demand

Due to the many possibilities, with new applications found every day, there is an increasing need for different microparticles in chemistry and medicine. To meet this demand, production requires precision, huge production volumes, and a wide choice of particles, suited for different purposes. However, current production methods are either too slow or not precise enough. For example, the microfluidic chip method is based on a tiny fluid stream that runs through a micro channel. The fluid, also called ink, is designed to harden when exposed to UV light, similar to dental fillings in dentistry. When exposing this ink by a pulse of UV light, a small piece is briefly exposed to UV and will consequently harden: a microparticle is born. But using microchannels is too slow to produce large amounts of particles.

Different shapes

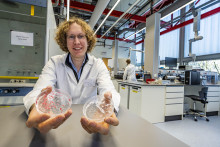

Recently, the UT published a different procedure for the microparticle production. ‘Our team developed a completely new method to accurately produce large quantities of microparticles in all shapes and sizes, without using microchannels,’ says Claas Willem Visser, assistant professor at the Engineering Fluid Dynamics Group of the UT. ‘We used so-called in-air polymerization of liquid jets, where a tiny ink stream of just 0,1 millimeter is propelled into the air, and subsequently briefly exposed to UV light, hardening it.’

Depending on the duration of the UV exposure, different shapes can be made: a brief pulse will result in a cylinder-shaped microparticle, while a longer UV pulse results in elongated microparticle, a micro fiber. This method is accurate as the shape can be exactly defined, while it is also suitable for producing large volumes.

Solid polymer

However, the method was not easily established. ‘To make a liquid jet stream was in principle no problem, but the smaller the stream, the faster it has to be propelled,’ Jieke Jiang, lead author of the study, explains. ‘That also means that there is little time to expose the ink to UV, only a few milliseconds.’ The scientists solved this problem by using very powerful and fast UV lights in combination with fast-hardening ink. This was just the beginning of an exciting development to make more different-sized and -shaped microparticles. The scientists found out that these could be created by manipulating the UV exposure. For example, when only one side of the ink stream was UV exposed, a shape resembling half a cylinder could be made.

Create micro lenses

The method was also adapted for printing applications. Here, the continuous ink stream was broken in a controlled way by vibrating the nozzle, creating a train of individual ink droplets. If these droplets land onto a flat surface, they spread out and stick to it, forming micro-lenses. Without UV light, these lenses would stay liquid. ‘Surprisingly, if we expose the droplets to UV light before they land on the surface, they will only become fully solid after impact. This is due to a short delay between UV exposure and solidification,’ Jiang says.

‘The beauty of this method is that we can control the curvature of these spheres by changing the UV exposure. Low UV exposure leads to relatively flat spheres and vice versa. This way we can create micro lenses with a controlled focal length.’ Collecting thousands of these droplets on a solid surface is done in only a few seconds, creates many powerful micro lenses that are able to manipulate light. This could for example be useful to make solar panels more efficient by directing light from the edges towards the actual solar cells.

Fundamental approach

As a second step to streamline the production and design of different microparticles, the scientists modelled the process, to better predict when and how specific microparticle shapes could be made. The model uses a combination of fluid dynamics, materials science and the intensity, duration and location of UV exposure. This way, the scientists gain more insight into the process and know better what buttons to push to make it working. ‘Our research started with a very fundamental and basic approach, but we are now starting to see some really practical applications,’ Visser says. ‘Designing and producing large amounts of precisely sized and shaped microparticles opens many doors in different scientific and industrial fields.’