The almost unlimited consumption of our society puts a large pressure on the earth’s natural resources. According to a study by the OECD, 62 billion tonnes of raw materials, like minerals, wood, metals, and fuels are extracted each year. About one fifth of these resources will eventually end up as waste, due to the absence of effective recycling plants and technologies. These unsustainable practices result in pollution and, in the long term, depletion of resources.

‘Today’s waste stream still contain a lot of valuable resources and molecules that we can recycle’

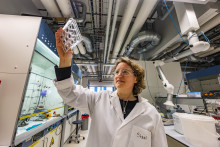

‘Today’s waste stream still contain a lot of valuable resources and molecules that we can recycle,’ De Beer says. ‘For a more sustainable society and eventually a completely circular economy in 2050, better resource recovery and reuse from waste are therefore essential.’ However, resource retrieval is not always easy, since the existing waste streams contain a complex mixture of substances. In addition, many reusable molecules are present in only low concentrations, while they might also be tightly bound to other waste components present. Separation and recycling are thus challenging to say the least. They require novel technologies that can operate at high precision and low cost to efficiently retrieve specific molecules at the source.

Precision separation

The ReCoVR program aims to develop a new class of separation technologies, by using a combination of fundamental and applied research aimed at developing new coatings that can capture specific molecules. ‘That means we need to find a way to selectively retain certain molecules on a special ‘sticking’ surface,’ Sissi de Beer explains. ‘This is not so difficult; you only need to find a material where the molecules like to adhere to. The main challenge is to release them in a controlled way again once they are captured.’

Using electricity, we can tune the affinity of the target molecules to different electrode materials. Thereby, the electrodes will selectively attract and retain the molecules we want to capture. By applying an electric field, the electrode becomes attractive to the molecules such that they will adsorb on the electrode. By switching off the electric field, the electrodes will no longer attract the molecules, and are subsequently released. This results in clean, energy-efficient, precision separation processes.

‘Our new technology only uses electricity’

De Beer: ‘Traditional separation technologies, that are based on temperature and pressure-driven processes, require treatment of the entire waste volume. Costs of these waste treatments may be as high as 50 % of the total production costs. Our new technology only uses electricity to locally charge the electrodes and is much more cost-effective, especially if we apply it at the source, before the waste stream is mixed with other surplus substances.’

Toxic solvents

ReCoVR will focus on the Dutch chemical and food producers to recover valuable molecules since these industries use as much as 40 % of the total energy consumption and 60 % of all water used in The Netherlands. The scientists focus on the retrieval of a several main substances at the source. For example, protein recovery is important, since only about a quarter of all proteins produced are actually consumed.

Another important resource is clean water. About 15 % of all water used can’t be treated and recovered using the traditional cleaning technologies. Using electrical separation could contribute to treating this last portion of difficult to clean wastewater. Another compound to salvage is the carbon monoxide produced by the steel industry. While this substance is a valuable resource for the chemical industry, and could in theory be reused, it can’t be recovered yet and is burnt to carbon dioxide and wasted. Flavor molecules are another important group of molecules that will be included. These plant-based chemicals often are extracted using toxic solvents. This ‘dirty’ process can also be replaced by using clean electrical separation and extraction methods.

Understand and control

To develop electrically-based separation technologies for all these different substances, a lot of expertise is required in many different fields. ‘For example, we aim to combine different existing technologies to identify and quantify the proteins present in potato waste from the food industry,’ De Beer says. ‘In addition, we will develop new materials and coatings for the electrodes used in our recovery technologies. Graphite-like materials, that have many pores and consequently a huge surface, are suitable candidates. This allows more target molecules to stick to it.’ To better understand and control the separation process, lab experiments will be used to generate data to build theoretical models that can simulate the procedure. The effect of, for example, the electrode coating material on the separation can thus be simulated and understood. A next step is to manipulate and improve the technology by applying different electrode materials and coatings.’

‘We have a fantastic team to run this project,’ De Beer says. ‘Universities, governments, companies and different institutions join forces and it is my dream that with this program The Netherlands will establish a leading position in the global transition to a circular economy. I’m excited to get started!’