About a third of all energy used in the EU comes at the cost of road and air transportation and this amount will only increase in the future. Making vehicles lighter is an obvious measure to reduce energy use as well as CO2 emissions. Plastics are lighter than conventional materials for cars and planes, such as steel and aluminum. However, these materials should not only be lightweight, they also need to be strong enough to withstand large forces. In addition, they have to be recyclable, to reduce energy use and save on new materials.

‘These plastics are made of long molecules, polymers, that are entangled, just like spaghetti on a plate’

‘The so-called thermoplastic polymers have excellent properties that meet some of the standards,’ says project leader Remko Akkerman from the Faculty of Engineering Technology. ‘These plastics are made of long molecules, polymers, that are entangled, just like spaghetti on a plate. This gives the material some strength. In addition, they can easily be molded when heated and pressed in any desired shape.’ Due to their versatility, these plastics have many applications in today’s society. They are for example applied in computer and telephone housing, but also in beer crates and packaging and storage materials. They are also suitable for mass production and can, in principle be reused by melting and remolding, over and over again.

Promising materials

However, thermoplastics on their own are unsuitable to replace steel and aluminum in cars and planes. The entangled polymers are just not strong and stiff enough in larger constructions. This can be solved by combining the plastic with carbon or glass fibers for reinforcement, resulting in a so-called composite material. If these fibers are oriented in the right direction, the material becomes much stronger and is not easily deformed. In addition, these composites are extremely lightweight, much lighter than steel or even aluminum, while their production is fast, and recycling is relatively easy. These materials are therefore the number one choice to replace traditional, heavier materials. And the savings on weight are impressive.

‘Weight reduction of 50 % is feasible’

‘When applying these light-weight composites in steel cars, a weight reduction of 50 % is feasible, while in aluminum aircraft parts, a 30% reduction can be achieved,’ explains Akkerman. Thousands of small parts made of these composites are currently applied in modern civil aircraft, but, according to the professor, now is the time to start developing the technology to make much larger structures. Using the right methodology, such big composite structures can be built up from smaller pieces. ‘Better materials and manufacturing methods are key to make such large composite structures for application in road transport and aviation. In theory this is possible because this material can be welded by heating it and subsequently pressing pieces together.’ Also, additional reinforcing ribs can be welded on a larger surface for extra stiffness and strength.

Unpredictable performance

However, there are some hurdles to take before the widespread use of large thermoplastic composites structures is possible. Although the basic ideas and technologies are there, one of the bottlenecks is the strength of the welds: these still have an unpredictable performance and are thus not necessarily reliable enough. Manufacturing big car or plane sections is consequently a challenge, involving a lot of trial-and-error before safe operations can be guaranteed.

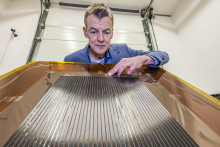

Therefore, the focus of ENLIGHTEN is to create welds in composite materials with a predictable strength by studying and understanding both the material and the welding process. To completely recognize the strength and functioning of a weld, and manipulate and improve its overall performance, the scientists require detailed knowledge about the material properties. In addition, they need to know how the thermoplastic and the fibers behave during welding. Experiments to test the weld strength, analyze why and where failures occur and how this relates to the production process, are therefore crucial elements of the research.

‘We will specifically study the weld strength at different scales,’ Akkerman explains. ‘The molecular scale includes the structure and strength of the polymer chains. One scale higher, we study the strength of the thin individual composite layers, that measure about 0,1 – 0,2 millimeters, and how they are arranged inside the weld. At the largest scale we evaluate the properties of the whole product.’ These different scales are evidently coupled: the structure at the smaller scales, for example the molecular and layer level, translates into properties at larger scales.

Optimize the process

Gathering all this information helps to manipulate and improve the weld at the molecular, individual layer and final product levels. These data, including material properties, like stiffness, viscosity, heat conductivity and strength, can be used to build simulation models. ‘These simulations help us to better understand welding, which welding techniques work best, and what determines weld strength,’ says Akkerman. ‘We will also simulate different welding methods on different materials, to choose and optimize the process and the design for the best performance.’ Ultimately, this should all lead to a science-based design and manufacturing system of large composite parts at an industrial scale.

Wide variety of expertise

The tasks within the project are complicated and require a large coherent program, where different participants contribute with a wide variety of expertise in different fields. Therefore, a large consortium of universities, companies and institutes, are involved to achieve the ambitions. ‘We have excellent knowledge on thermoplastic composites in the Netherlands,’ Akkerman says. ‘Together with our research partners in TU Eindhoven and Delft, the University of Warwick, HAN and Saxion, we have all relevant expertise available to make ENLIGHTEN successful.’ With the team, ENLIGHTEN aims to pave the way to a more sustainable mobility in the five years to come.