08:30 Every day, the lab in the Horst building welcomes about a dozen researchers, including PhD candidates, Postdocs, Master students or visiting students from all over the world. At first glance, the SRL team is very international and interdisciplinary, but none of the members say no to a good cup of morning coffee.

09:30 Professor Sarthak Misra directs the SRL at the UT, as well as its satellite-lab in Groningen. ‘As the principal investigator, I’m not always in the lab, but all the projects fall under my research interests and I regularly spend time with my students,’ says Misra. The main focus of the lab is to design a range of minimally invasive surgical instruments and microrobotic systems. The devices you can find in the lab can be divided into three main categories: needle steering devices, continuum robotics and medical microrobotics.

10:30 ‘We create custom-made devices, which take years to develop. Currently you can see about seven setups in the lab. Each student is responsible for their own project, their setup is like their baby,’ clarifies Misra. SRL is also equipped with rapid prototyping facilities such as a 3D printer and a laser cutter, which students often use to make components necessary for their projects.

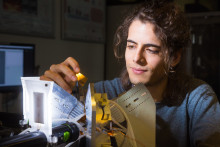

11:30 A lot of time in the lab is spent by running various experiments. In order to do that, students first need to prepare their setups. The first step is naturally the assembly of the device, which is exactly what Federico Ongaro is working on these days: ‘This setup is called Bat-Mag. It will be used for steering microrobots using magnetic field. The device creates magnetic field, through which the microrobot is then controlled. The microrobots are able to swim through veins, remove clogs or take biopsies. This technique could therefore be used for minimally invasive surgeries.’

13:30 To prepare a setup for experiments, students often need to spend some time programming or coding. ‘I work with both hardware and software. And sometimes, I’m of course busy with organizational issues, such as writing papers,’ describes Jakub Sikorski. ‘If I do that or work on software, I just spend a significant part of the day in front of the computer.’

15:30 ‘For example, now I was working on the camera used inside the Big-Mag,’ continues Sikorski, whose main focus is a device lovingly named ‘Big-Mag’, a setup intended for steering catheter by using magnetic field. ‘I saw a picture of Big-Mag in its early stages of development and I got a bit nostalgic. It was like seeing a baby picture of your child and then looking at the kid, who is now all grown up and dressed up. I feel like a proud father,’ he says, confirming Prof. Misra’s earlier comment about the students’ relationship to their projects.

16:30 When all the hardware and software is ready, researchers can conduct experiments. At the moment, the lab contains the aforementioned realistic heart model, which is used for testing a setup that aims to insert catheter inside a beating heart. Ultrasound is used to visualize how exactly the catheter moves inside the heart. In later stages of development, most of the surgical instruments are also tested on animals or human cadavers, but those tests are done in a hospital, not at the UT campus.

17:30 Although the lab is open anytime researchers need to use it, it usually becomes empty at about 6 p.m., when most students head home.

The full photo story can also be found in the November issue of UT Nieuws magazine.